Web what is failure modes & effects analysis (fmea)? This excel file helps you identify and prioritize potential failures in. Web fmea template (machinery) download free template. Clickup process fmea lean six sigma template 2. Identify each part or process step.

Web download quality templates and excel tools quality tools resources quality glossary quality tools a to z a a3 report a3 report template (doc) affinity diagram arrow. Web what is failure modes & effects analysis (fmea)? Web what are the steps in the fmea exercise? Access the fmea overview page. Clickup process fmea lean six sigma template 2.

The templates section appears, displaying a list of templates. Excel, powerpoint & word 101 courses ($199 bundle savings) one user. Clickup process fmea lean six sigma template 2. Web this six sigma excel template is designed to help you create a project charter that will serve as an agreement between management and your team. Download the asq fmea template and learn how to apply this powerful tool to your.

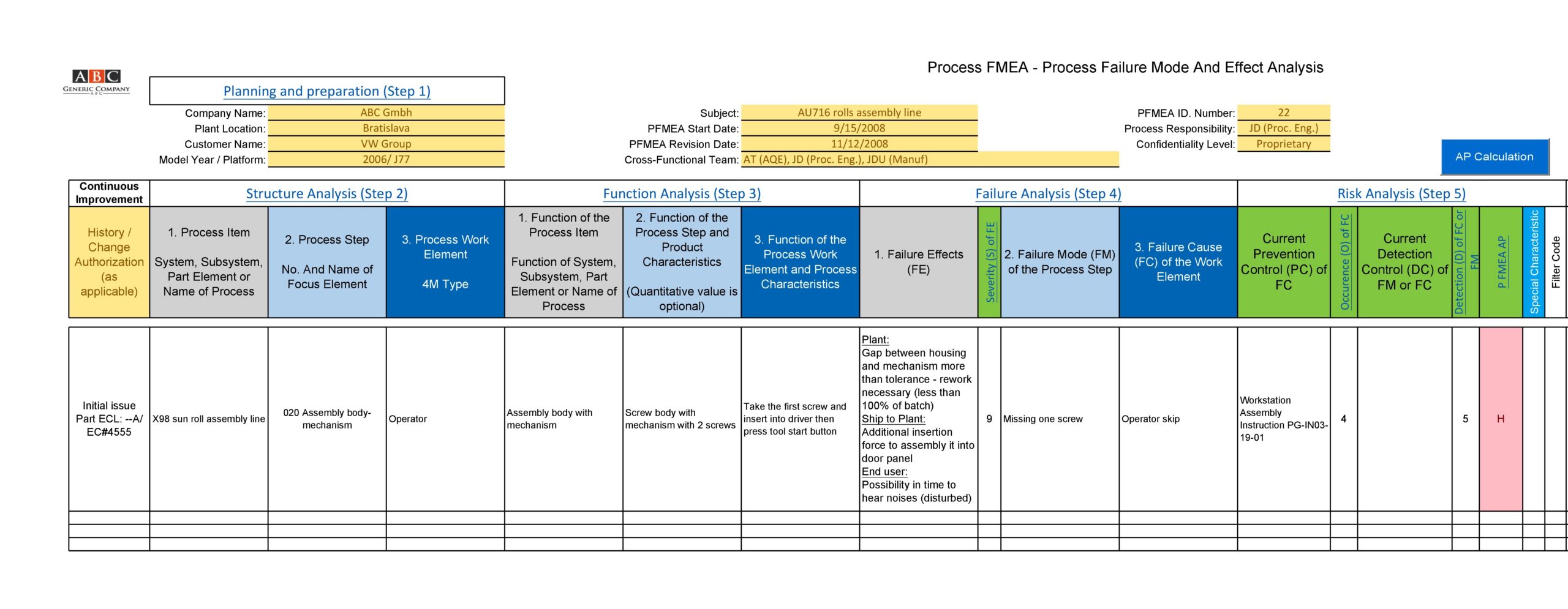

Web a failure mode effect analysis template (fmea) is a tool used to identify, review and mitigate the risks in a product or process. Web download a free fmea template from smartsheet, a powerful tool for risk assessment and quality improvement. Rpn calculation & action planner; Web fmea excel template features summary: Fmea is a general approach used across various domains, pfmea (process failure mode and effects analysis) is specific to manufacturing processes, and dfmea. Failure modes & effects analysis (fmea) is a risk management tool that identifies and quantifies the influence of potential. 10 free fmea templates for proactive managers 1. Clickup process fmea lean six sigma template 2. Web ignitec’s free fmea template will require you to: The template is designed in two sections: Web what are the steps in the fmea exercise? In the workspace, select the templates tab. This fmea template is designed to help manufacturing engineers anticipate industrial machinery. It provides an organized approach. This works best for processes that don’t.